Basic introduction:

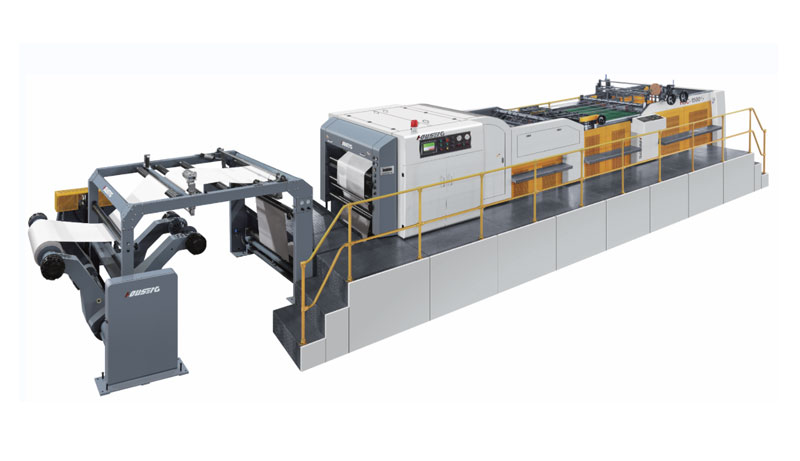

Classic double-helical knife slitting machine, stable operation, widely used in a variety of paper types

Basic introduction:

Classic double-helical knife slitting machine, stable operation, widely used in a variety of paper types

1.HSC-S series double knife sheeter adopts advanced design of synchronic rotary which are driven directly by high power AC servo motor with high accuracy and clean cut.

2.And using our patent with embedded cutting head design, that its cutting cross profile is straight and not pulling out fibers, this is key point to eliminate hairs of paper. Widely used for cutting cardboard, coated paper, Kraft paper, culture paper, art paper, duplex,packaging paper, etc. up to 1000gsm.

3.HOUSENG machine is dedicated to produce sheet cutter , Products are well used and verified by almost all top cosmetics and pharmaceutical packaging customers, and promise their is no risk for long term running of your products in future. Consider this kind of machine to improve quality and save cost, To improve efficiency .

Applicable Type: cardboard paper, coated paper, kraft paper, cultural paper, writing paper, double gummed paper, gloss photo paper, gold and silver cardboard, aluminum paper, laser paper, packaging paper etc.

| ITEM | PARAMETERS | Cutting Length | Speed(m/min) | Speed (cuts/min) |

| Model | HSC 1500S/1700S/1900S | 1600≤X | 210 | <131 |

| Cutting Pattern | Double rotary sheeter | 1400≤X<1600 | 260 | ≥162<185 |

| Range of Gram Weight | 80-1000gsm | 1200≤X<1400 | 280 | ≥200<233 |

| Max.RollDiameter | 1800mm(71")Max | 1000≤X<1200 | 300 | ≥250<300 |

| Max.Paper Cutting Width | 1500mm/1700mm/1900mm | 800≤X<1000 | 300 | ≥300<375 |

| Total Power | 90kW | 700≤X<800 | 300 | ≥375<400 |

| Cutting Length | 400-1650mm | 650≤X<700 | 230 | ≥328<353 |

| Cutting Accuracy | +/-0.15mm | 600≤X<650 | 180 | ≥246<300 |

| Air Compressor Requirement | 0.8MPa | 550≤X<600 | 160 | ≥266<290 |

| Weight | 21000kgs/23000kgs | 500≤X<550 | 120 | ≥218<240 |

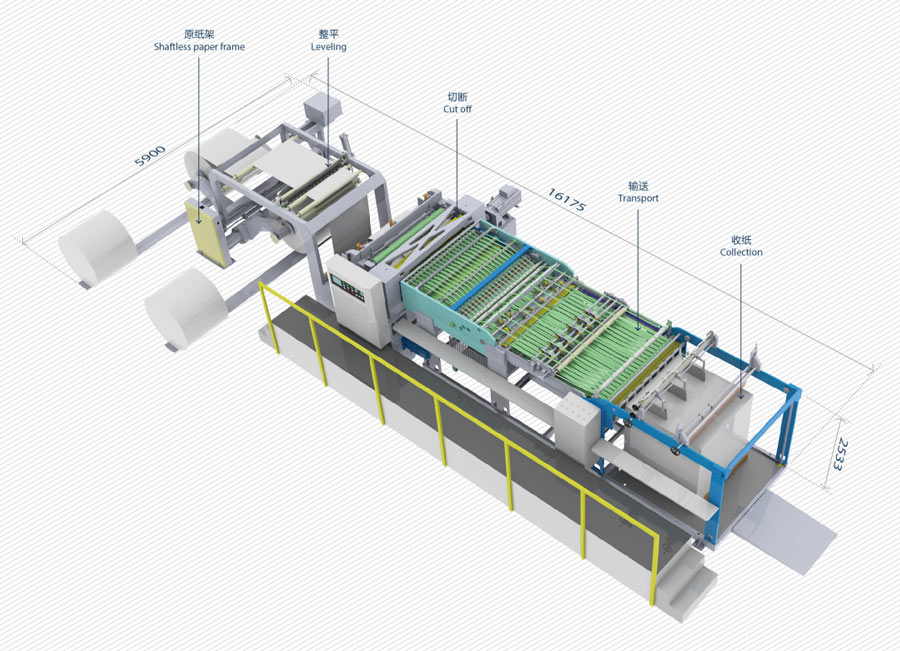

| Overall Dimension | L16175×W5900×H2533mm | 450≤X<500 | 90 | ≥180<200 |

| 400≤X<450 | 70 | ≥155<175 |

HSC-S series run with high precision, stable operation, low energy consumption and high effciency, are developed by technology from German and decades years of experience we have. lt's widely used in the paper industry and printing industry.

Double rotary spiral cutter rollers can cut paper clearly in less force; German precision bearing and cutting knife achieve high cuting precision; Touch interface control is easy to operate: The reasonable infection device can remove the cured paler effectively, thus strenath tension ofthe paper rol. heets can directly into printing without trimming after cutting, which do improve economic effciency,reduce production costs

According to HOUSENG MACHINE, are mainly used for paper cutting in Paper Mill, Printing House and etc.

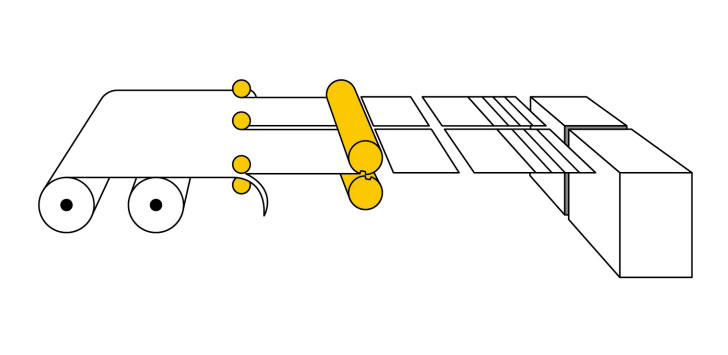

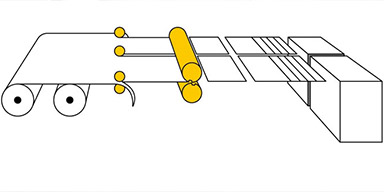

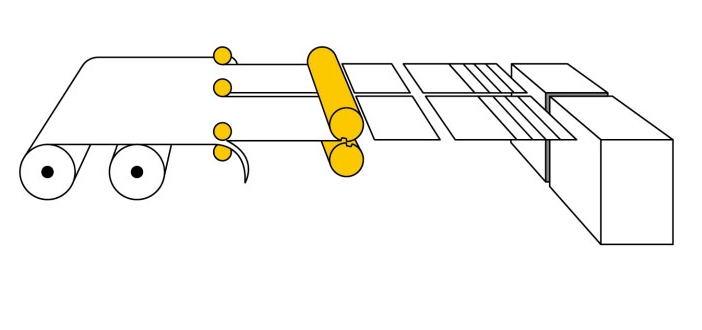

Mainly process including: Unwinding—Feeding—Cutting—Conveying—Collecting .

1. Automatic Splicer

High performance automatic twin-head paper splicer with Taiwan control system, can splice paper aromatically, perform out by high flexilbility and long service life, suitable for base paper which grams of 80g/m²-400g/m².

2. Slitting & Trimming Knives Automatic Change System

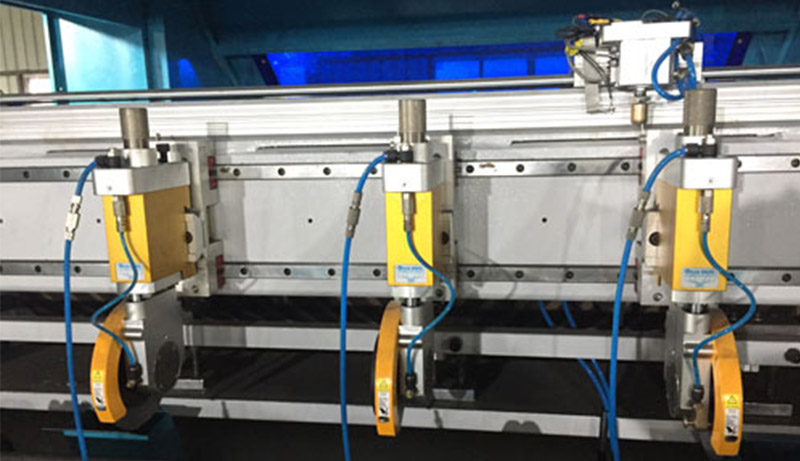

APS-L series high-precision automatic positioning and slitting system matches high-precision sliting requirements. Intelligently, accurately and rapidly, the sliting and trimming knives is auto-changing by manipulator, thus greatly improving the ability and effciency when product variety changing. According to different cutting reguirements, it can work out different cuthing solutons by coordinating with different knife, such as automatic type, manual type, connected type and pressure cutting type slitting knife, and electronic knife, etc.

3. Platform Weighing Scalesystem

Material Weighing:The weighing scale installed at the lifting platform can display the weight of the paper stack timely for recording. t uses German technology and adopts four-horizontal and four-vertical structure to avoid scale damage and measurement errors caused by the displacement of paper stacks.

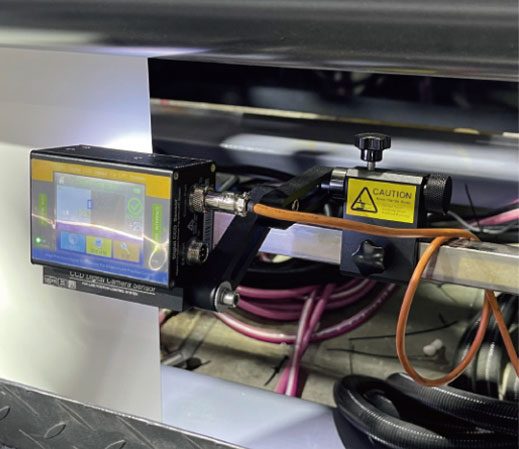

Stack Height Veasurement:The height of the paper stack can be measured by laser rangefinder. The laser sensor emits laser pulses, which are reflected back to the receiver by the stack, and it's height can be calculated by the fight time of the laser pulse or the amplitude ofthe photoelectric signal.

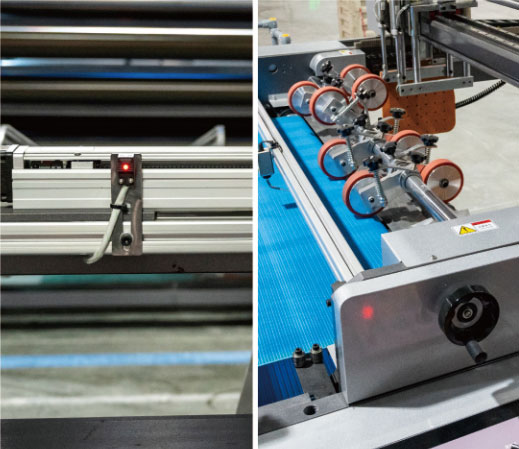

4. Infrared Align Auto-Adjustment

Paper Rolls alignment: the operator only needs to input the width in the touch screen, which can realize the auto-align-ment of the front and back paper rolls, avoid the loose and wrinkles caused by the wrong alignment, reduce waste. This system co-works with the order auto-changing system, and all controlled by servo motor. it adopts CcD correction sensor and supports EPC and LPC line tracking.

5. Color Code Sensor

The high precision detector, supplied by SlCK, a German brand, can accurately identify extremely fine color diferences with the sensing distance tolerance up to ±5mm.

6. Dedusting Rollers

The blue high-viscosity roller can effectively adsorb the dust on the the paper, and then white dedust roller (driven by the cylinder) removes the dust on the bule. lt's easy to tear off the viscous film on the white one.

7. Pallet Pusher

The lateral pallet auto-pusher is developed independently by HAOSHENG. The servo motor drives the pushrod to push pallets from crossrange, thus gear up for collection.

8. Auto-Material Flow

The tray chain conveyor mainly adopts 5 rows of straight chain conveyor, and uses the motor drive the material trans-port in ultra-low position straightly, which is a modular design and reach high degree of standardization. Hidden photo-electric switch can prevent photoelectric sensor or cardboard damage, servo motor built-in to save space, reversible operation, flexible adjustment, basically maintenance-free.

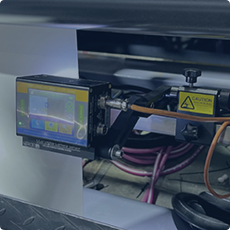

9. Inkjet Coding System (Inkjet Platform)

This part is composed of dedust system, high-speed inkjet system, intelligent positioning system, energy-saving LED curing system, image detecton system, data management system, high-speed waste removal svstem, tvpesetting software and printing software. Born for the packaging industry.

HSC1500S/1700S/1900S high-precision double-spiral slitting machine is a new product developed by our company using German technology and combined with many years of experience in producing paper cutters, which is high-precision, stable in operation, energy-saving and efficient. Widely used in cardboard, coated paper, kraft paper, cultural paper, offset paper, high-gloss photo paper, gold and silver cardboard, aluminum foil paper, laser paper, tobacco and wine packaging paper, etc.

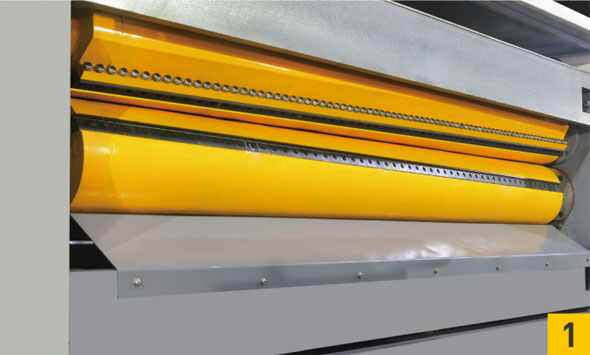

The cutter roller adopts a double-rotating spiral cutter roller design, which has small cutting force, clean paper cross-section, high efficiency, and stable rotation; German precision bearings and cutting knives provide high cutting accuracy; light-touch computer interface control, easy to operate; well-designed feedback The curling device can effectively remove the curl of the paper roll, making the paper flatter, which is more conducive to the stability of the paper roll tension.

|

|

|

|

|

Double Rotary Sheeter Group Precision rotary sheeter groove is processed byimported advanced |

|

|

Electric Control Part German imported Siemens PLC and The United States Emerson servo |

|

Slitting Knife Top shear air knife innovative desian enables pneumatic movement of |

|

|

Conveying Overlap Part A precision structure can adjust the synchronous deceleration wheel, |

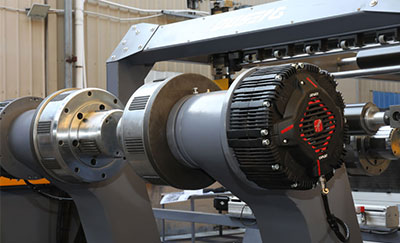

| Cutting Unit The double KNIFE cutting unit has a synchronic rotary cutting knife like scissors on the material to make a smooth and accurate cutting for paper from 150gsm and up to 1000gsm.The knife roller is using the most powerful driver from UK CT. Precision rotary sheeter groove is processed by imported advance processing center with high accuracy and stability, High quality gear box ,using no clearance design gear. which guarantees the stability of the tool body during high-speed operation, completely solve the problem of scratches and light spots, after cutting the edge is neat and smooth, clean cut. |

|

|

Double Arm Unwind stand with web tension controls and pneumatic brake units. Adopt Italian RE control system and pneumatic components are adopted to guarantee the stable operation of the brake control system and the accuracy of every aerodynamic action. |

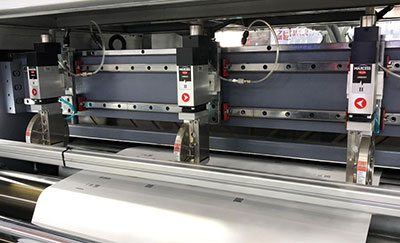

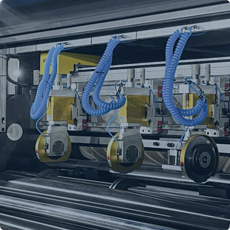

| Three sets of MAXCESS pneumatic slitting knife ensure stable and clean slitting . High rigid tool post article can be applied to 400cut/min speed environment, improve the production efficiency and ensure the material quality stability. |

|

|

Electric control part Adopt German imports of Siemens PLC and UK OF CT servo drive control system, make the operation more convenient, automation, cutting length, number and the total number of finished products, etc., can be directly in touch screen input. High efficiency and energy saving of high power CT servo drive rotary knife shaft, and cooperate with the energy storage tank, effectively reduce electricity consumption, improve the efficiency, reduce the production cost. |

| Transportation parts Patent device-A precision structure can adjust the synchronous deceleration wheel, easy to operate, it is effective to protect surface of paper, so there will be no scratching on surface, and also will not have the facula whenever speed is high or low . |

|

|

The delivery section using automatic set paper equipment Lift stacked set paper , the paper stack to a considerable height, |

| Reject Gate In the end of the first conveyor belt is placed a sheet rejecting device, which can be inserted by the operator in the starting phase for the first sheets. The start of rejecting device is manual by pushing the ON.OFF button to act the air cylinder of reject gate. |

|

|

The new Anti curvature device (2 set de-curl ) Effectively remove the curl of the roll to make the paper more flat, more conducive the paper roll tension stability. |

AUTOMATIC SPLICER

SITTING & TRIMMING KNIVES AUTOMATIC CHANGE SYSTEM

PLATFORM WEIGHING SCALE SYSTEM

INFRARED ALIGN AUTO-ADJUSTMENT

COLOR CODESENSOR

DEDUSTING ROLLERS

PALLET PUSHER

AUTO-MATERIALFLOW

INKJET CODING SYSTEM

Optional

Functions Details

2025/03/21

2025/03/21In today’s fast-paced manufacturing and printing industries, efficiency, accuracy, and material optimization are non-negotiable. Enter roll paper to sheet cutting machines and twin knife cutter machines—two groundbreaking technologies transforming how businesses handle large-scale material processing. Whether you’re in packaging, publishing, or label production, understanding these innovations is key to staying competitive.

Roll paper to sheet cutting machines are engineered to convert continuous rolls of paper, film, or other substrates into precisely sized sheets. This process eliminates manual handling, reduces waste, and ensures uniformity—critical for industries demanding high-volume output with zero tolerance for errors.

Key Advantages:

Speed & Scalability: Modern machines process rolls at speeds exceeding 200 meters per minute, slashing production time while maintaining razor-sharp precision.

Waste Reduction: Advanced sensors and programmable logic controllers (PLCs) auto-adjust cutting parameters, minimizing offcuts and maximizing material utilization.

Versatility: Compatible with diverse materials—from delicate tissue paper to rigid cardboard—these machines adapt seamlessly to evolving production needs.

For businesses transitioning from roll-based workflows to sheet formats, investing in a roll-to-sheet cutter is a strategic move toward leaner, more profitable operations.

While traditional single-knife cutters have long dominated the market, twin knife cutter machines are redefining the benchmarks for speed and accuracy. Equipped with dual synchronized blades, these systems deliver simultaneous cuts, enabling unmatched consistency even at breakneck speeds.

Why Twin Knives?

Synchronized Cutting: Dual blades operate in tandem, eliminating blade deflection and ensuring clean, burr-free edges.

High-Speed Performance: Ideal for ultra-high-volume environments (e.g., packaging lines), twin knife systems reduce cycle times by up to 40% compared to single-blade alternatives.

Durability: Built with hardened steel blades and robust frames, these machines withstand heavy-duty use while maintaining micron-level precision.

Industries like flexible packaging, where substrates vary in thickness and texture, benefit immensely from the twin knife’s ability to handle complex materials without compromising quality.

Printing & Publishing: Convert massive paper rolls into standardized sheets for books, magazines, or marketing collateral.

Packaging: Slit laminated films or corrugated boards into custom sizes for boxes, pouches, or labels.

Label Manufacturing: Achieve flawless cuts for adhesive labels, ensuring seamless application in automated bottling or logistics systems.

Textiles & Nonwovens: Process fabric rolls into sheets for medical supplies, hygiene products, or industrial applications.

Automation Level: Opt for PLC-driven models with touchscreen interfaces for effortless operation and real-time adjustments.

Cutting Accuracy: Look for laser-guided alignment and servo-driven blade systems (±0.1mm tolerance).

Safety Features: Blade guards, emergency stops, and IoT-enabled diagnostics are critical for worker protection and minimal downtime.

As Industry 4.0 reshapes manufacturing, roll-to-sheet cutters and twin knife machines are evolving with smart features. Predictive maintenance, AI-driven optimization, and cloud-based monitoring are no longer futuristic concepts—they’re today’s standards. Companies embracing these technologies gain not only a competitive edge but also a pathway to sustainable growth through reduced energy consumption and material waste.

In an era where precision and efficiency dictate profitability, upgrading to advanced cutting solutions like roll paper to sheet machines and twin knife cutters is no longer optional—it’s imperative. By investing in these technologies, businesses unlock higher productivity, lower operational costs, and the agility to meet ever-changing market demands.

Ready to transform your production line? Explore cutting-edge solutions today and cut through limitations—literally.

Zhejiang Haosheng Intelligent Equipment Co., Ltd. offers state-of-the-art roll-to-sheet and twin knife cutting systems tailored to your industry’s needs.

2025/03/14

2025/03/14In today’s fast-paced industrial landscape, efficiency and precision are non-negotiable. For industries relying on specialized paper products—from packaging to food manufacturing—the demand for cut sheet paper solutions has never been higher. Enter the next generation of industrial innovation: Smart Industrial Paper Cutters, engineered to deliver unmatched accuracy, speed, and versatility for applications ranging from pre cut baking paper sheets to parchment paper pre cut sheets.

Modern manufacturing requires equipment that adapts to diverse materials and specifications. Traditional cutting methods often fall short when handling delicate or specialized materials like silicone-coated baking sheets or heat-resistant parchment paper. Smart Industrial Paper Cutters address these challenges head-on with:

Ultra-Precision Cutting Technology

Equipped with AI-driven laser guidance and servo motors, these machines achieve tolerances as tight as ±0.1mm. This ensures flawless results for pre cut baking paper sheets, where uneven edges could compromise functionality in commercial ovens or packaging lines.

Multi-Material Compatibility

Whether it’s parchment paper pre cut sheets for food-safe packaging or heavyweight cardstock for printing, smart cutters automatically adjust blade pressure and speed. Advanced sensors detect material thickness and texture, eliminating waste and reducing downtime.

Scalable Automation

Integrated IoT connectivity allows operators to program custom cutting patterns via a user-friendly interface. Batch orders for cut sheet paper products can be completed 50% faster than conventional systems, meeting high-volume demands without sacrificing quality.

The versatility of Smart Industrial Paper Cutters makes them indispensable in sectors where precision matters most:

Food & Baking: Perfectly sized pre cut baking paper sheets streamline production for bakeries and frozen food manufacturers, ensuring consistent sizing for trays, liners, and wrappers.

Packaging: Customizable parchment paper pre cut sheets cater to eco-friendly packaging trends, offering grease-resistant and compostable solutions for gourmet foods and confectionery.

Printing & Office Supplies: High-speed cutting of cut sheet paper boosts productivity for stationery suppliers and print shops, delivering uniform stacks of letterhead, labels, and marketing materials.

Beyond performance, these cutters prioritize sustainability. Precision cutting minimizes material waste by up to 30%, while energy-efficient motors reduce power consumption. For businesses transitioning to eco-conscious practices—such as replacing plastic wraps with parchment paper pre cut sheets—this technology aligns with global green initiatives.

Investing in Smart Industrial Paper Cutters translates to:

Reduced Operational Costs: Lower labor requirements and material waste.

Enhanced Product Quality: Flawless pre cut baking paper sheets and parchment paper pre cut sheets elevate brand reputation.

Future-Proof Flexibility: Adapt to new materials or client specifications effortlessly.

As industries evolve, so must their tools. Excellent Version Double Rotary Sheet Cutting Machine redefine what’s possible for cut sheet paper production, offering precision, speed, and adaptability that traditional machines cannot match. Whether your focus is on food-grade pre cut baking paper sheets, sustainable parchment paper pre cut sheets, or high-volume printing materials, this technology ensures your business stays ahead in a competitive market.

Upgrade to precision. Embrace the future of industrial cutting.

2025/03/07

2025/03/07In the packaging, printing, textile and other industries, accurate and efficient sheet cutting is the core link of the production chain. Traditional cutting tools often face problems such as low efficiency, large errors, and material waste, and the innovation of sheet cutting tools, especially the emergence of Excellent Version Double Rotary Sheet Cutting Machine, has completely broken this bottleneck. This article will take you to explore the operating principle, technical advantages and how this cutting-edge equipment reshapes industry standards.

The core of the double rotary cutting machine lies in its unique "double blade rotation design". Unlike traditional unidirectional cutting, its two high-precision circular knives rotate at high speed in opposite directions to form a composite effect of "shear force + tension", which not only increases the cutting speed by more than 50%, but also achieves ultra-high precision of ±0.15mm. This design is particularly suitable for the seamless slitting of materials such as cardboard, coated paper, kraft paper, cultural paper, writing paper, double-sided paper, glossy photo paper, gold and silver cardboard, aluminum paper, laser paper, and packaging paper.

HAOSHENG launched the new product in November 2023, combining years of production experience, capturing customer needs, taking into account efficiency and stability, the EXC series performs well in short-distance cutting, fully demonstrating that Haosheng has always been dedicated to innovation.

Speed improvement: Compared with the standard, the maximum speed has increased by 73.8%.

High-efficiency power system: equipped with a 108kW servo motor, the maximum cutting speed is 500 times/minute, supporting 24-hour continuous operation; it performs particularly well in the cutting length range of 400-65omm

Intelligent deviation correction device: real-time monitoring of material deviation through photoelectric sensors, automatic adjustment of knife distance, and reduction of scrap rate to less than 0.5%;

Multi-function: This product has added material weighing and paper pile height measurement functions, and a socket workbench to pay attention to every small need of customers and improve production experience.

With the advancement of Industry 4.0, the new generation of double rotary cutting machines have integrated the Internet of Things (IoT) module. Users can remotely monitor the status of the equipment, predict faults, and optimize cutting parameters in real time through mobile phone APP. At the same time, the green coating blade technology launched by Haosheng extends the blade life to 3 times that of ordinary materials, further reducing industrial waste.

From manual cutting knives to intelligent double rotary cutting machines, every innovation of sheet cutting tools is driving the manufacturing industry towards a more efficient and precise direction. The Excellent Version Double Rotary Sheet Cutting Machine is becoming a benchmark for industry upgrades with its disruptive technology. If you pursue the ultimate production efficiency and quality, this device may be your ultimate answer.

Click to learn more technical details ➔ Zhejiang Haosheng Intelligent Equipment Co., Ltd.

GET A QUOTE