01

02

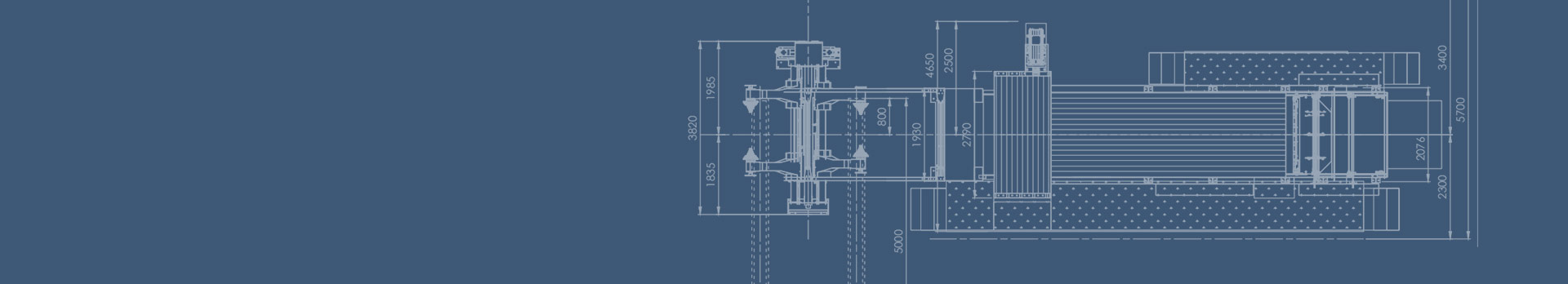

APS-L series high-precision automatic positioning and slitting system matches high-precision slitting requirements. Intelligently, accurately and rapidly, the slitting and trimming knives is auto-changing by manipulator, thus greatly improving the ability and efficiency when product variety changing.

According to different cutting requirements, it can work out different cutting solutions by coordinating with different knife, such as automatic type, manual type, connected type and pressure cutting type sltting knife, and electronic knife, etc.

03

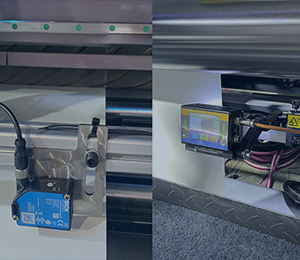

Material Weighing:The weighing scale installed at the liting platform can display the weight of the paper stack timely for recording. It uses German technology and adopts four-horizontal and four-vertical structure to avoid scale damage and measurement errors caused by the displacement of paper stacks.

Stack Height Measurement:The height of the paper stack can be measured by laser rangefinder. The laser sensor emits laser pulses, which are reflected back to the receiver by the stack, and it' S height can be calculated by the flight time of the laser pulse or the amplitude of the photoelectric signal.

04

Paper Rolls alignment: the operator only needs to input the width in the touch screen, which can realize the auto-align-ment of the front and back paper rolls, avoid the loose and wrinkles caused by the wrong alignment, reduce waste.

This system co-works with the order auto-changing system, and all controlled by servo motor. It adopts CCD correction sensor and supports EPC and LPC line tracking.

05

06

07

08

The tray chain conveyor mainly adopts 5 rows of straight chain conveyor, and uses the motor drive the material transport in ultra-low position straightly, which is a modular design and reach high degree of standardization.

Hidden photoelectric switch can prevent photoelectric sensor or cardboard damage, servo motor built-in to save space, reversible operation, flexible adjustment, basically maintenance-free.

09