In today’s fast-paced manufacturing and printing industries, efficiency, accuracy, and material optimization are non-negotiable. Enter roll paper to sheet cutting machines and twin knife cutter machines—two groundbreaking technologies transforming how businesses handle large-scale material processing. Whether you’re in packaging, publishing, or label production, understanding these innovations is key to staying competitive.

The Evolution of Roll-to-Sheet Cutting Technology

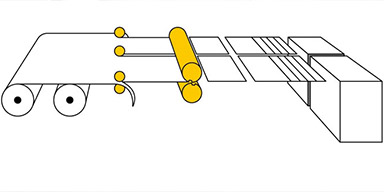

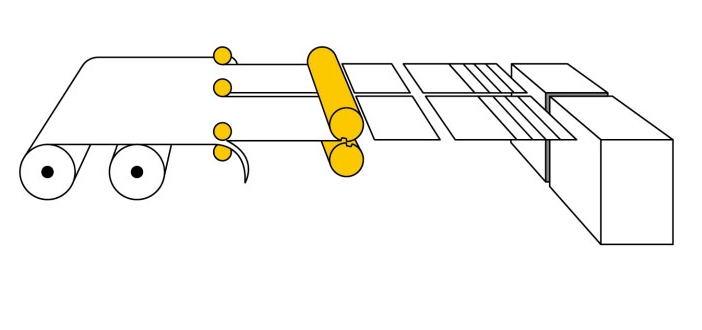

Roll paper to sheet cutting machines are engineered to convert continuous rolls of paper, film, or other substrates into precisely sized sheets. This process eliminates manual handling, reduces waste, and ensures uniformity—critical for industries demanding high-volume output with zero tolerance for errors.

Key Advantages:

-

Speed & Scalability: Modern machines process rolls at speeds exceeding 200 meters per minute, slashing production time while maintaining razor-sharp precision.

-

Waste Reduction: Advanced sensors and programmable logic controllers (PLCs) auto-adjust cutting parameters, minimizing offcuts and maximizing material utilization.

-

Versatility: Compatible with diverse materials—from delicate tissue paper to rigid cardboard—these machines adapt seamlessly to evolving production needs.

For businesses transitioning from roll-based workflows to sheet formats, investing in a roll-to-sheet cutter is a strategic move toward leaner, more profitable operations.

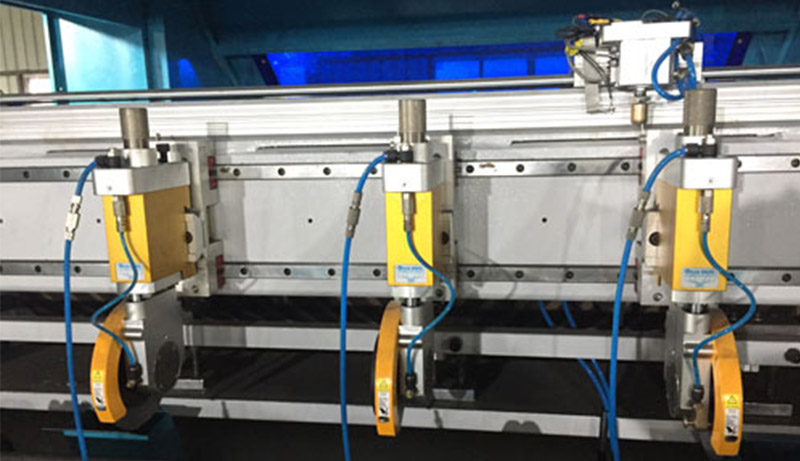

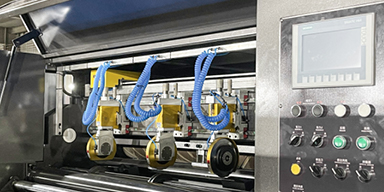

Twin Knife Cutter Machines: Doubling Down on Precision

While traditional single-knife cutters have long dominated the market, twin knife cutter machines are redefining the benchmarks for speed and accuracy. Equipped with dual synchronized blades, these systems deliver simultaneous cuts, enabling unmatched consistency even at breakneck speeds.

Why Twin Knives?

-

Synchronized Cutting: Dual blades operate in tandem, eliminating blade deflection and ensuring clean, burr-free edges.

-

High-Speed Performance: Ideal for ultra-high-volume environments (e.g., packaging lines), twin knife systems reduce cycle times by up to 40% compared to single-blade alternatives.

-

Durability: Built with hardened steel blades and robust frames, these machines withstand heavy-duty use while maintaining micron-level precision.

Industries like flexible packaging, where substrates vary in thickness and texture, benefit immensely from the twin knife’s ability to handle complex materials without compromising quality.

Applications Across Industries

-

Printing & Publishing: Convert massive paper rolls into standardized sheets for books, magazines, or marketing collateral.

-

Packaging: Slit laminated films or corrugated boards into custom sizes for boxes, pouches, or labels.

-

Label Manufacturing: Achieve flawless cuts for adhesive labels, ensuring seamless application in automated bottling or logistics systems.

-

Textiles & Nonwovens: Process fabric rolls into sheets for medical supplies, hygiene products, or industrial applications.

Choosing the Right Machine: Key Considerations

-

Automation Level: Opt for PLC-driven models with touchscreen interfaces for effortless operation and real-time adjustments.

-

Cutting Accuracy: Look for laser-guided alignment and servo-driven blade systems (±0.1mm tolerance).

-

Safety Features: Blade guards, emergency stops, and IoT-enabled diagnostics are critical for worker protection and minimal downtime.

The Future of Cutting Technology

As Industry 4.0 reshapes manufacturing, roll-to-sheet cutters and twin knife machines are evolving with smart features. Predictive maintenance, AI-driven optimization, and cloud-based monitoring are no longer futuristic concepts—they’re today’s standards. Companies embracing these technologies gain not only a competitive edge but also a pathway to sustainable growth through reduced energy consumption and material waste.

Conclusion

In an era where precision and efficiency dictate profitability, upgrading to advanced cutting solutions like roll paper to sheet machines and twin knife cutters is no longer optional—it’s imperative. By investing in these technologies, businesses unlock higher productivity, lower operational costs, and the agility to meet ever-changing market demands.

Ready to transform your production line? Explore cutting-edge solutions today and cut through limitations—literally.

Zhejiang Haosheng Intelligent Equipment Co., Ltd. offers state-of-the-art roll-to-sheet and twin knife cutting systems tailored to your industry’s needs.

2025/03/21

2025/03/21